Torque Testing Instrument Bottle Lid Torque Meter

Product Details:

- Specimen Size Diameter 10~120 mm

- Application Measuring opening/closing torque of bottle caps

- Response Time Instantaneous

- Max Height 180 mm

- Power Supply AC 220V, 50Hz

- Equipment Type Torque Testing Instrument

- Frequency 50Hz

- Click to view more

Torque Testing Instrument Bottle Lid Torque Meter Price And Quantity

- 1 Set

- 395.00 - 1099.00 USD ($)

Torque Testing Instrument Bottle Lid Torque Meter Product Specifications

- High precision, easy-operation, robust construction

- Standard 3/8 fitting

- Aluminum alloy body

- 0-10 Nm

- Benchtop

- 85% RH

- 1% F.S.

- Approx. 6.5 kg

- 220V

- 1 specimen at a time

- Digital LCD

- Suitable for standard bottle lids

- RS232/USB

- 0.01 Nm

- 10C ~ 40C

- 0-10 Nm

- Manual

- Torque Testing Instrument

- 50Hz

- Laboratory, industrial quality control

- 10 Nm

- Digital Control

- AC 220V, 50Hz

- 180 mm

- Instantaneous

- Measuring opening/closing torque of bottle caps

- Diameter 10~120 mm

- 0~150 mm (Adjustable)

- Manual operation

Torque Testing Instrument Bottle Lid Torque Meter Trade Information

- shenzhen,guangzhou

- 300 Set Per Month

- 7 Days

- All India

Product Description

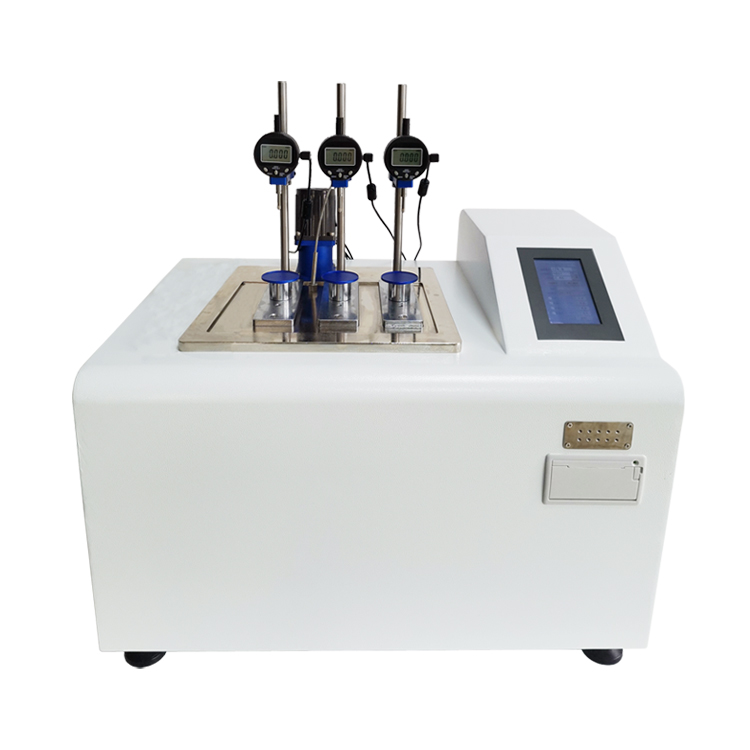

Torque Testing Instrument Bottle Lid Torque Meter ANL-P1

Digital bottle lid torque meter is an intelligent multi-functional measuring instrument which is designed for testing various kinds of bottle lid torque. It main used in testing and calibrating tighten force, parts torsional destructive testing, etc. With features of simple operation, high precision, easy to carry, complete functions etc. It is widely used in various kinds of electric, light industry, machinery manufacturing, research institutions, etc.

Main Features:

1)High precision, high resolution, quick sampling speed, full-screen display.

2)Adopting high precision torque sensor, with torque direction display.

3)Upper and lower limit value setting, red and green indicating lights and buzzer audible and visual alarm.

4)Three units can be switched each other (N.m, Kg.fcm, Lb.in).

5)Real-time, peak, automatic peak three models of optional switch.

6)Use USB interface and PC communications, synchronous test function can connect to the computer, computer synchronous display test force graph and the detailed test process, can save, print, doing all sorts of analysis.

7)Peak holding, remove automatically function, remove time to set freely.

8)Large storage, can save 99 groups of test data.

9)Without automatic shutdown function, time can be set freely.

Specification:

Model: ANL-WP1

Printer: No

Measuring range/ Division value: 1.0000/0.0001N.m/ 10.200/0.001Kg.cm/ 8.850/0.001 Lb.in

Peak Value Sampling Frequency:2000HZ

Power: 7.2V 1.2VX6 Ni-MH Battery group

Charging Time: 4-6 Hours

Accurate and Reliable Torque Measurement

This meter guarantees high precision for bottle lid torque testing, delivering results with an accuracy of 1% F.S. and a resolution of 0.01 Nm. Its instantaneous response time means users can quickly evaluate cap performance, making it invaluable for quality control procedures in both laboratory and factory settings. The non-slip rubber grip and adjustable stroke accommodate various bottle lid sizes for versatile application.

Simple Operation and User-Friendly Features

With manual control and digital interface, this instrument provides convenient operation for users. The digital LCD display offers clear readings, and user calibration support ensures ongoing accuracy. The foam-lined carton packaging, benchtop mounting, and standard 3/8 port size make installation simple, while robust construction provides durability.

FAQs of Torque Testing Instrument Bottle Lid Torque Meter:

Q: How does the bottle lid torque meter measure cap twisting torque?

A: The device determines the opening or closing torque of a bottle cap through manual twisting in either clockwise or anticlockwise directions. It records torque values instantly via the digital LCD display, ensuring accurate results for each test specimen.Q: What is the maximum number of test data sets this instrument can store?

A: This torque meter can store up to 100 individual test data sets, allowing users to archive and analyze multiple torque measurements efficiently before downloading or exporting results.Q: When should calibration be performed on this torque testing instrument?

A: User calibration is recommended before beginning a new testing series, after any significant environmental changes, or according to your laboratory/quality control schedules to maintain precision. The instrument supports easy calibration directly by the operator.Q: Where can this torque meter be used effectively?

A: It is suitable for laboratory environments, industrial quality control rooms, and any setting requiring reliable measurement of bottle lid torque, particularly for bottles with cap diameters between 10 and 120 mm.Q: What is the process for conducting a bottle cap torque test with this instrument?

A: To conduct a test, securely mount the bottle in the instrument, adjust the grip width and test stroke, then manually twist the cap using the device controls. The torque value will be displayed instantly. Data can be stored or exported via RS232/USB interfaces.Q: How does using this torque meter benefit quality control routines?

A: The instrument ensures consistency and accuracy in measuring bottle lid torque, helping companies maintain packaging standards, prevent leakage or over-tightening, and comply with regulatory requirements. Efficient data storage and robust design enhance workflow and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+